Aug 29, 2023 | CAS Assembly Tooling and Services, Crib Service and Support, News, project management

🌟Testimonial Tuesday!🌟

👉Great to have received these comments recently and it’s not every Tuesday it’s 🌟Testimonial Tuesday!🌟

From : Senior Director at a High value automotive company.👌

” I wanted to take a moment following the line start-up this morning. This was to express my thanks for Matt (Brooke) on the successful delivery of the Wheel Fit Station move project over the Summer Shutdown period.

Matt, and the team he assembled, showed outstanding dedication to safety. Also, meticulous attention to detail throughout the entire shutdown period. Please pass on my thanks to the full contracting team.

The ability to manage and contain the complexities and challenges that arose during the project (the bent torque tube and broken spring balancer) was notable. These ultimately could have risked our ability to build vehicles today.

In addition, the method by which the project was managed day to day has set a new standard for how high-risk projects are managed on site.

Please accept my thanks and know that your team’s dedication has made a lasting impression.”

It’s great to receive testimonials now and again and for this project. We are particularly grateful to our very own Matt Brooke for taking on the challenge with dedication and pride for CAS Assembly Tooling and Services yet again. Great to have him and his expertise on board.

If anyone wishes to hear more about our projects and how we can help them in any industry, not only the automotive, you are welcome for a chat. Please call Neil Evans or Jason Kane to talk about anything project management! Call on 01213271700

Dec 12, 2022 | Crib Service and Support, HAVS, News, Tooling

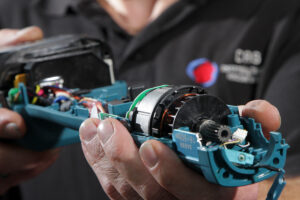

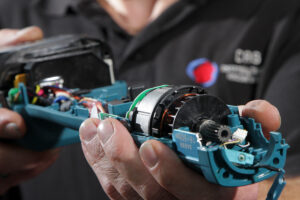

Hand-Arm Vibration Syndrome (HAVS) is the main concern posed by exposure to vibration. Sometimes this is called as ‘white finger’ or ‘carpal tunnel’ syndrome. HAVS is caused by the transfer of vibration through a workers hands and arms, in as little as 6 months. Nerve damage and restricted blood flow to the hands and fingers can occur. This causes the debilitating symptoms and effects known as Hand Arm Vibration Syndrome.

What Are The Effects of HAVS/Hand-Arm Vibration?

Some of the common symptoms of HAVS, as described by the HSE, are listed below. Many sufferers experience a wide range of debilitating effects due to the condition that can impact in both their day to day lives and in their ability to work.

- Pain, tingling and total loss of feeling

- Reduced strength and grip ability

- Muscle wasting

- Reynaud’s disease (White fingers that become painfully red)

The loss of feeling, and pain often results in sufferers struggling to work. This especially can happen in the industry that caused their condition. Because of this, in the day to day life, simple tasks such as doing up buttons and picking things up become challenging especially as the condition often deteriorates once developed. These symptoms make it clear that HAVS is a serious disease, which operators should be protected from.

What Work Causes HAVS?

Any work that includes consistent or frequent exposure to vibration through the hands or arms can lead to debilitating and permanent health problems. Most commonly this is caused by the use of a tool that vibrates during use, but it is important to recognise how broad this category is and the large number of operators that may be at risk.

Industries that can be affected are as follows :

- Road and rail workers

- Construction Industry

- Estate management

- Forestry

- Foundries

- Heavy Engineering

- Shipping

- Lab work

- Medicine

Examples of equipment and tools that pose a risk are as follows:

- Chainsaws

- Hammer Drills

- Lawn Mowers

- Saws

- Chisels

- Grinders

- Impact Wrenches

- Drills

- Sanders

- Strimmers/Trimmers

The most effective way of controlling & monitoring exposure is by carrying out HAV testing which we do at Cas Assembly and Tooling. Here is some more information and is really important you take care of employees by having these tools tested on a regular basis.

Repairs at CAS Assembly Tooling and Services

If you need any further information, have any queries or would like to arrange for your tools to be calibrated, let us know on 0121 327 1700.

Oct 18, 2022 | Crib Service and Support, News, Tooling

A recent crib project – CAS Assembly Tooling and Services

A recent crib project was that our client wanted to reinstate an assembly line for a future product. CAS Assembly Tooling and Services were going to be in their element here! We were asked to go and assess the project and produce a solution for the required work. We got the production line plans and looked at each station individually. Due to this being an already established site with lots of tooling already purchased for various other projects we started with what spare tools that could be utilised. At the same time we were keeping in mind the critical spare tools that are required for the everyday running of the site.

By doing this step first we were then able to look and what gaps we had to fill with new products, this also allowed our client to understand the budget required making their investment as cost effective as possible.

What challenges did we face?

We were faced with some challenges along the way with delivery schedules due to a global component shortage meaning dates would slip. With knowing this we worked with the customer to produce a plan allowing us to keep the project on track. We then waited until the new equipment and tools were delivered.

Time was a big influence for this project, and as we had many stations to furnish out, we created a station standard form for the installation of hardware. This detailed everything required in each station and what level of network was required. Understanding our client’s needs allowed us to make improvements to the already existing dedicated tooling network infrastructure in place. We utilised the previously abandoned network cabinet and added a link between production areas. This enabled a more fluid tooling network environment.

This was such a successful project that it was noticed across other departments, that we received some very nice feedback for a happy customer.

Another satisfied customer for CAS Assembly Tooling and Services and a pat on the back to Matthew Brooke and the Service and Support team for taking control of this project from beginning to end.

Tools being fixed at CAS HQ