Feb 24, 2023 | CAS Assembly Tooling and Services, News

🌟Job Opportunity 🌟

Overview.

CAS Assembly Tooling and Services is a market leader in the supply, installation, and servicing of industrial power tooling. We have a great team working all over the UK and we are recruiting for a technician to repair, service and support tooling based in a Tool Crib at a leading automotive OEM in St Athan, South Wales.

Roles and Responsibilities.

- Assessing and testing various pneumatic tools.

- Fault diagnosis for a range of power tools.

- Repairing a range of pneumatic, hydro-pneumatic and battery powered tools.

- Carrying out routine maintenance on industrial power tooling.

- Record details of all repairs carried out and parts used etc.

- Stock inventory management to ensure critical spares are replenished.

- Basic knowledge of excel, word and other computer-based programs for data entry.

A mechanical or maintenance background would be an advantageous but not essential as full training will be given. Route for progression may involve training to develop the following skills and competencies.

- Assessing and testing various electric tools.

- Fault diagnosis for a range of electric tools.

- Configuration of DC Tooling systems with Wi-Fi communications.

- Carrying out annual service and calibrations on DC tooling systems.

- Providing Line technical support for customer production teams.

Additional Information.

Much of the work involves mechanical disassembly, inspection, identification of worn or damaged parts and replacing these. The tools are then tested and in some cases the calibration of their transducers checked and amended where necessary.

Our customer has a wide range of hand tools for which CAS are responsible for within the customers assembly facility located in St Athan, South Wales. Part of this role will involve occasional rotations to the customers sister site in Gaydon, Warwickshire being required. Some of the tools are Pneumatic, others are mains powered and the rest are battery powered via Lithium-Ion type power pack.

The more advanced tooling systems are connected to the customers high level production control systems and may need to be replaced and reconfigured with Wi-Fi and other parameters to function correctly.

We have a simple reporting system where data for each tool visited is entered into a spread sheet. This raw data is then collated and reported directly to the customer so competence in data entry is important.

This role is based within our customers assembly facility forming part of their mission critical team, so professionalism and customer care are paramount to the successful development of any applicant taking on this opportunity.

It will include a shift rotation pattern such as early, day shift and late shifts. There may be occasions that overtime will be required on weekdays and or weekends to support the customers production schedules. Please note that some tools are heavy so a degree of manual labor and lifting will be required. You will be required to always adhere to the customers health and safety policies and procedures. A simple Site induction will be carried out prior to gaining access to the customers site as your normal place of work.

- A full British driving licenses is essential to this position due to the location of customers sites.

- There are excellent facilities on this site which are available to all CAS employees.

- The salary band for this role is £22,000 – £24,000 with an increment on completion of probation.

- Salary is negotiable dependent upon experience and relevant skill sets.

- Projected Start Date for these positions will be Monday 1st of May 2023.

To apply please contact Matt Brooke at mbrooke@cas-ltd.uk.com before closing date 10/03/2023.

Feb 3, 2023 | CAS Assembly Tooling and Services, Desoutter, Tooling, tooling solutions

Let’s introduce Roger King!..to the team at CAS Assembly Tooling and Services.

Roger started with Atlas Copco in 1992, in an admin/tech support role then went on the road in a sales role in 1996. This was where he first met Dave Embley, Managing Director of CAS Assembly Tooling and Services… back in the day!

Roger moved on to Martlets Air Power (Winchester) still promoting Atlas Copco Tools. When Martlets was taken over by Atlas he was given the Atlas Copco Tools Distribution. This continued for a number of years and then he joined Desoutter in 2011 of which CAS now work alongside so he knows the products. Knowledge is power!

In 2016 Roger joined AP Tools, and then Ray Moss Tools (Harlow) and continued with them until 6 months ago. This is when he saw an opportunity to join CAS!

So, he has many years experience in providing tooling solutions, both directly to customers and through distribution. Roger loves working at CAS as we have such a great portfolio and reputation. It has given him some great opportunities in the South of England. He loves being part of the well established team at CAS and in a thriving company.

Hobbies!

In his spare time Roger goes to as many gigs as possible loves live music especially the Foo fighters and Stereophonics. He can regularly be found at his local pub watching live bands too!

When not at work, Roger loves to ride his mountain bike as much as he can. When the opportunity arises, he likes to go to Spain for some off road motor biking.🚲

It’s great to have Roger on board. 😊

If you are looking for tooling solutions, Roger’s the man that can in the South of England! Give him a call on 07487 615488 .

Roger King joins CAS in July 2022

Dec 22, 2022 | News

Merry Christmas from the CAS Team!🎄

We close our office and workshop tomorrow for Christmas!

Wishing all of our customers and followers a very Happy Christmas and a Prosperous New Year! 🎅

Have a great Christmas break one and all, from the CAS Team!🙂

Dec 12, 2022 | Crib Service and Support, HAVS, News, Tooling

Hand-Arm Vibration Syndrome (HAVS) is the main concern posed by exposure to vibration. Sometimes this is called as ‘white finger’ or ‘carpal tunnel’ syndrome. HAVS is caused by the transfer of vibration through a workers hands and arms, in as little as 6 months. Nerve damage and restricted blood flow to the hands and fingers can occur. This causes the debilitating symptoms and effects known as Hand Arm Vibration Syndrome.

What Are The Effects of HAVS/Hand-Arm Vibration?

Some of the common symptoms of HAVS, as described by the HSE, are listed below. Many sufferers experience a wide range of debilitating effects due to the condition that can impact in both their day to day lives and in their ability to work.

- Pain, tingling and total loss of feeling

- Reduced strength and grip ability

- Muscle wasting

- Reynaud’s disease (White fingers that become painfully red)

The loss of feeling, and pain often results in sufferers struggling to work. This especially can happen in the industry that caused their condition. Because of this, in the day to day life, simple tasks such as doing up buttons and picking things up become challenging especially as the condition often deteriorates once developed. These symptoms make it clear that HAVS is a serious disease, which operators should be protected from.

What Work Causes HAVS?

Any work that includes consistent or frequent exposure to vibration through the hands or arms can lead to debilitating and permanent health problems. Most commonly this is caused by the use of a tool that vibrates during use, but it is important to recognise how broad this category is and the large number of operators that may be at risk.

Industries that can be affected are as follows :

- Road and rail workers

- Construction Industry

- Estate management

- Forestry

- Foundries

- Heavy Engineering

- Shipping

- Lab work

- Medicine

Examples of equipment and tools that pose a risk are as follows:

- Chainsaws

- Hammer Drills

- Lawn Mowers

- Saws

- Chisels

- Grinders

- Impact Wrenches

- Drills

- Sanders

- Strimmers/Trimmers

The most effective way of controlling & monitoring exposure is by carrying out HAV testing which we do at Cas Assembly and Tooling. Here is some more information and is really important you take care of employees by having these tools tested on a regular basis.

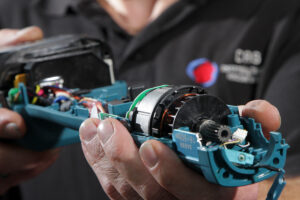

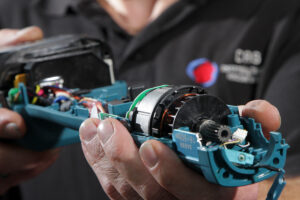

Repairs at CAS Assembly Tooling and Services

If you need any further information, have any queries or would like to arrange for your tools to be calibrated, let us know on 0121 327 1700.

Nov 22, 2022 | News, Tooling

The CAS Assembly Tooling and Services Head Office Repair Centre in Birmingham is able to support a key customer with over 14000 key engineers covering the UK repairing various essential tools.

🔧🔩Tools often get damaged and are used until they break and the CAS team are on hand to repair them when they do.

For this particular customer, engineers whom are on the road constantly, meet at a central point to drop off repairs, and they are then sent to us.

Thankfully we have experienced technicians on hand and ready to repair them quickly and efficiently.